Surface Finishing Service

Find our selection of surface finishing services. Get your metal and plastic parts CNC machined and apply a secondary finishing. CNC machined parts bead blasted, anodised or powder coated.

As Machined

Straight off the machine with no additional treatment. Suitable for: Most Materials Additional Cost: None Most surface finishes either add material to coat, or remove material to smooth. Coming straight from the machine the part retains the accuracy of cnc, however also shows the marks from cutting. In some cases this can be accepted, and in others desirable. The standard roughness off a machined part is 3.2 μm (0.0032mm) With further operations roughness can be reduced to 0.4 μm (0.0004mm) This will add cost to the final part. PROs Most accurate (Best Tolerance) No Additional Cost CONs Visible Cutting Marks No Protection if material is not resistant to chemicals or corrosion

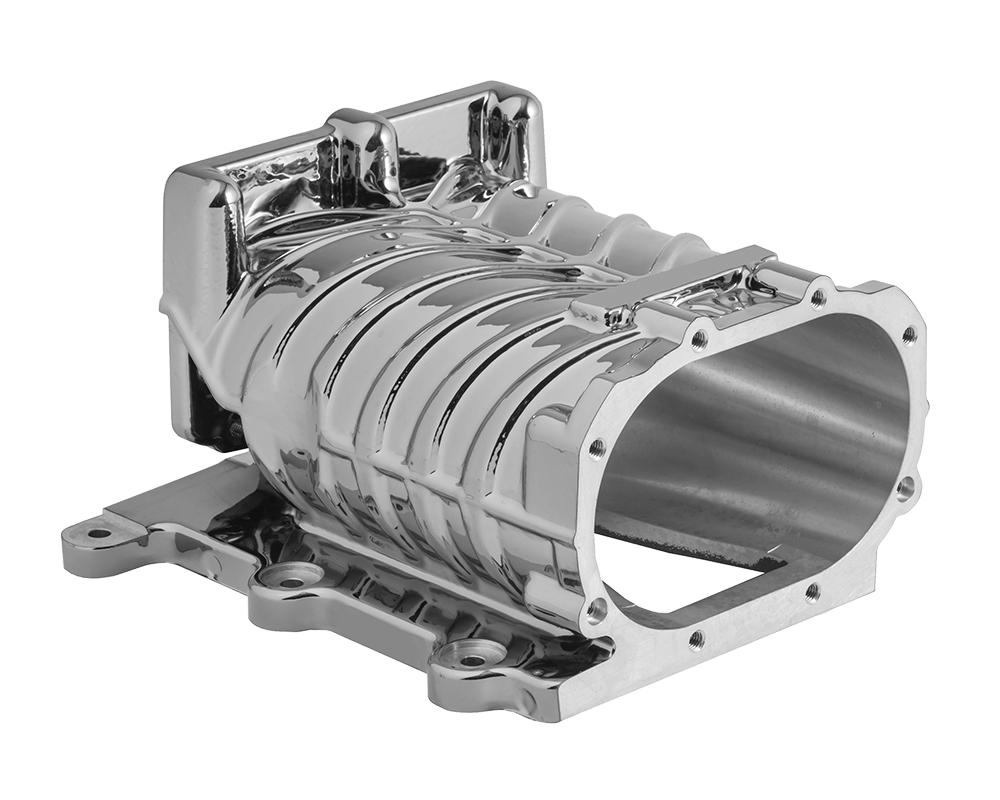

Blasting Service

Blasting Service (Bead or various abrasive grades.) Suitable for: Most Materials Additional Cost: Low/Mid Blasting smooths out the surfaces of the part, removing the tool marks. It is normally used where there is an aesthetic requirement, and sometimes as a pretreatment for other finishes or coatings. PROs Unified Matte/Satin Finish Low Cost Available in Different Roughness CONs Will Affect Critical Dimensions No Protection if Material is not Resistant to Chemicals or Corrosion

Anodising service

Colour or clear (natural material colour) Suitable for: Aluminum, Titanium Additional Cost: Low/Mid Anodising is a process where the part is immersed in an electrolytic solution and electrical charge is passed through. This forms a very thin (8-25 μm) hard oxide layer on the surface which makes the part more durable and resistant to corrosion. The pores in the oxide surface also allow better adhesion for paints and coatings.By adding pigment to the solution the final part colour can also be changed as part of the process. Often the part is bead blasted, or polished before anodising to unify the surface and give higher visual quality. Parts can be anodised, machined back, then anodised again allowing for different finishes and colours PROs Durable and protects the Surface Quality Aesthetic Highly Colourable CONs Not the Most Durable Finish Limited To Aluminium/Titanium

Hard Anodising Service

Clear or Dark Colour. Suitable for: Aluminium Additional Cost: Low/Mid Similar to anodising the part is immersed in sulphuric acid with an electric charge. This results in a thicker (25 to as high as 150 μm ) oxide layer which is very durable and protects the aluminium from corrosion and damage. PROs Durable and protects the surface CONs Reduces Colour options Limited to Aluminum

Join us on the path to better, faster and stronger innovation

All uploads are secure and confidential.